Creating smarter plastic products for a better tomorrow

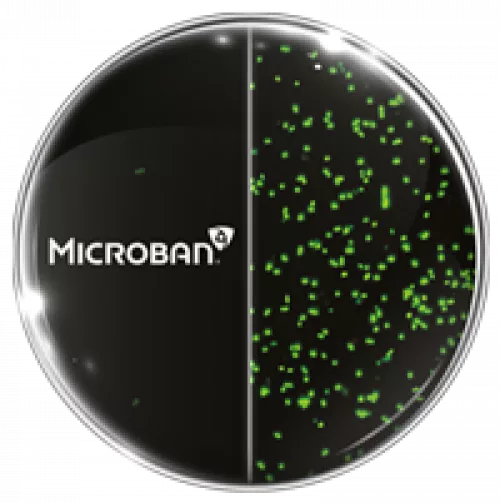

Built-in antimicrobial technology actively prevents microbial growth on plastic products, even in ideal temperature and humidity conditions. The result is a cleaner, fresher product that lasts longer, discourages waste, and encourages reuse.

Treatable polymer materials include Acrylonitrile Butadiene Styrene (ABS), Polypropylene (PP), Polystyrene (PS), Polyethylene (PE/LDPE), Polyvinyl chloride (PVC), and Polycarbonate (PC).

Common applications

Automotive

Regular cleaning is the key to maintaining cleaner interiors in cars, buses, trains, and planes. However, in many cases, cleaning isn’t always viable or realistic due to high traffic or the location of the surface. This can lead to damaging microbial growth, resulting in foul odors, diminished product performance and even cross-contamination onto other surfaces. Microban technology provides proactive protection against harmful bacteria, mold and mildew growth to deliver added peace of mind to passengers during every journey.

Construction

From performance and longevity, to ease of installation and upkeep, the criteria for building materials are vast. However, one key commonality is their exposure to moisture, humidity and natural food sources, all of which can cause microbial growth that can affect the aesthetics and durability of the product over time. Microban technology can be integrated into polymeric building materials such as PVC windows and pipes to help deliver permanent surface protection and enhance the lifetime of the product.

Packaging

Frequent handling, transportation conditions, and temperature changes can all lead to microbial contamination in plastic packaging. This not only causes premature material degradation but also encourages the development of stains and odors. With many brands shifting to sustainable packaging and adopting reuse/refill models, antimicrobial technologies can work to extend the aesthetics and shelf-life of packaging - making your sustainability goals more achievable and delivering added peace of mind.

Medical

Healthcare environments, whether large or small, provide ample opportunities for harmful microbes to grow and spread. High-touch surfaces such as bed rails, food trays, patient chairs and call bells, for example, can all benefit from built-in antimicrobial protection to help maintain cleaner medical facilities, reduce the risk of cross-contamination and deliver added peace of mind.

Homeware

Our hands are rarely far away from a gadget or product of some sort. From kitchen tools and home appliances to pet products and children's toys, consumer products are high-touch objects - which makes them breeding grounds for bacterial growth. Microban can help manufacturers create products that are protected against microbial growth for their expected lifetime.

Electronics

Microbes are no strangers to consumer electronics. Whether it is smartphones, laptops, or wearable technology, these devices have become an essential part of our daily lives and belongings - but rarely do they get cleaned. Microban technologies can be incorporated into a variety of components of many electronic devices to proactively protect the product from microbes.